6.777J/2.751J Material Property

Database

Material:

Titanium (PVD)

Application: Titanium has good adhesion to silicon and silicon dioxide and is frequently used

as an

adhesion layer for less adhesive metals such as gold

Deposition: Ti is usually

sputtered, using either standard magnetron sputtering, collimated sputtering or

ionized sputtering for good converage in contact of

via bottoms

|

Property |

Value |

Reference |

||||

|

Mass density |

4510 kg/m^3 |

CRC

Materials Science and Engineering Handbook, p.46 |

||||

|

www.matweb.com |

||||||

|

4.54 g/cm3 |

Handbook

of Chemical Vapor Deposition - Principles, Technology and Applications (2nd

Edition) ©1999 |

|||||

|

Young's modulus |

102.6 GPa |

Thin Solid Films,270(1995), p.263. Single layer deposited by DC

planar magnetron sputtering on to 2 inch oxidized Si<111>wafers

at ambient temp., using Ar as sputtering gas,Ar press=2 mT,for film

thickness from 0.1-2.0 um. |

||||

|

169.9 GPa |

Plummer, Table 11-4, page 697 |

|||||

|

123±21 GPa |

C O'Mahony,

M Hill, P J Hughes and |

|||||

|

www.matweb.com |

||||||

|

Poisson ratio |

0.34 |

www.matweb.com |

||||

|

0.32 |

http://www.rti-intl.com/tag/tiroom.htm |

|||||

|

Stiffness constants |

transformation at 800°C |

|

||||

|

Tensile or fracture strength Strain,limiting |

0.004 |

Thin film,used in semiconductor fabrication. IEEE,Micro Electro Mechanical Systems Workshop,Feb

1990, |

||||

|

Hardness |

81-143 kg mm-2 70 kg mm-2 |

Plummer, Table 11-4, page 697 |

||||

|

Residual stress on silicon |

439±41 MPa |

C O'Mahony,

M Hill, P J Hughes and |

||||

|

Specific heat |

522.5 J/kg/K at T=25 C. |

CRC Materials Science and

Engineering Handbook, p.261 |

||||

|

www.matweb.com |

||||||

|

|

Gremlin database (GM0303SF:Substances:Q08

hit 2, GRN 80946)

340051;LitLink; Vol. Ti: MVol.; Pages 156 - 160. 340075;LitLink; Jaeger, F. M.; Rosenbohm,

E.; Fonteyne, R.; PKNAAU; Proc. K. Ned. Akad. Wet.; Vol. 39; ( 1936 )

445 - 453. 340076;LitLink; Jaeger, F. M.; Rosenbohm,

E.; Fonteyne, R.; Rec. Trav.

chim.; Vol. 55; ( 1936 ) 618 - 625. |

|||||

|

Thermal conductivity |

||||||

|

21.9 W/m•K

at T=25 C |

Handbook

of Chemical Vapor Deposition - Principles, Technology and Applications (2nd

Edition) |

|||||

|

21.9 W/m/K at T=300 K. |

CRC Materials Science and

Engineering Handbook, p.274-276 |

|||||

|

Thermal

expansion coefficient: from |

9.5 ppm/K

in the0-300C range |

Bonding properties of metals anodically bonded to glass, Sensors and Actuators A:

Physical, In Press, Corrected Proof,

Available online |

||||

|

Thermal expansion coefficient |

8.41 x 10-6 C-1 |

Plummer, Table 11-4, page 697 |

||||

|

Melting Point |

1650 - 1670 °C 1660 °C |

Plummer, Table 11-4, page 697 Plummer, Table 11-2, page 688 |

||||

|

Dielectric constant |

Not found |

|

||||

|

Index of refraction (at 25C) |

|

Matlab plot made with 100

points from the paper: (Gremlin database) Antonov, V. N.; Kirillova,

M. M.; Krasovskiy, Ye. Ye.; Kurmayeva, L. D.; Minulina, N.

V.; FMMTAK; Fiz. Met. Metallov.; Vol. 69; ( 1990

) 83 - 88; Russian; PHMMA6; Phys. Met. Metallogr.

(Engl. Transl.);

Vol. 69/6; ( 1990 ) 78 - 83 |

||||

|

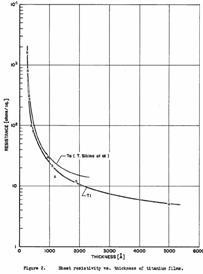

Electrical conductivity/resistivity |

|

Thin Films of

Titanium and Titanium Oxide for Microminiaturization |

||||

|

40-70 mW cm |

Plummer, Table 11-2, page 688 |

|||||

|

www.matweb.com |

||||||

|

43 mW cm |

Handbook

of Chemical Vapor Deposition - Principles, Technology and Applications (2nd

Edition) ©1999 |

|||||

|

~50mWcm Ohmic contact, stable up to 400C/30min |

Yale Stmusser , “CHARACTERIZATION IN SILICON

PROCESSING”, BUTTERWORTH-HEINEMANN |

|||||

|

Magnetic permeability |

1.00005 |

http://www.rti-intl.com/tag/tiroom.htm |

||||

|

Magnetic Susceptibility |

3.17 x 10-6 cm3/g |

http://www.rti-intl.com/tag/tiroom.htm |

||||

|

Piezoresistivity |

Not found |

|

||||

|

Piezoelectricity |

Not found |

|

||||

|

Wet etching method (these rates apply to sputtered

Ti under the conditions in |

Titanium wet etch: 20 H2O : 1

H2O2 :1 HF wet sink @ ~20C, etch rate: 1100 nm/min. |

|

||||

|

Isotropic silicon etchant

(126 HNO3 : 60 H2O : 5 NH4F), etch rate: 300nm/min. 10:1 HF (10 H2O: 1 49%HF) @ ~20C, etch rate: 1100

nm/min. 5:1 BHF @ RT: etch rate (fast) > 1000nm/min. Piranha |

|

|||||

|

Plasma etching method |

Ion milling KOH: makes the Ti layer "soft" (no

quantitative data) XeFe2 at 2.6mtorr in

homemade chamber, etch rate: 29nm/min (very selective over Al). |

|

||||

|

chlorine,

boron trichloride, nitrogen, etch rate:

0.7 µm/min. selectivity: photoresist-> 1:2, silicon dioxide-> 1:6, |

http://www.mems-

exchange.org/catalog/P2131/ |

|||||

|

Adhesion to silicon dioxide |

Good adhesion to silicon and to silicon dioxide |

Plummer |

||||

|

Biocompatibility |

|

The processing of

surgical implants from pure titanium |

||||

|

“For medical implants, titanium

is considered one of the most biocompatible materials available, especially

where direct contact to tissue or bone is required (i.e. endosseuos

dental implants or porous uncemented orthopedic

implants). See the individual titanium alloy datasheets for specific

applications.” |

www.matweb.com |

|||||

|

“Titanium

and titanium alloy implants are widely used in medicine for their

biocompatibility, good mechanical properties

and excellent corrosion resistance” |

C Madore

and D Landolt, “Electrochemical micromachining of controlled topographies on

titanium for biological applications”, J. Micromech. Microeng. 7 (1997)

270–275. Printed in the |

|||||

|

Hydrophobicity |

Surface contact angle: 54±5o – (moderately wettable / hydrophilic surface) |

Relationship

between surface properties (roughness, wettability)

of titanium and titanium alloys and cell behaviour |

||||

|

Vapor Pressure |

|

Gremlin database (GRN 16313) 340051;LitLink; Vol. Ti: MVol.; Pages 156 - 160. 340059;LitLink; Blocher, J. M.;

Campbell, I. E.; JACSAT; J. Am. Chem. Soc.; Vol. 71; ( 1949 ) 4040 - 4042. |

||||

|

Critical

Superconducting Temperature |

0.36 - 0.44 K |

www.matweb.com |

||||