| We must return to our ancestral lands and live in the traditional manner. |  |

| using local materials (garbage) we build the skin boat of our forefathers |  |

THE CORACLE |

| Laura test-piloting at the highspeed boatbuilding demonstration. This coracle is made from the basket part of a papasan chair with an armysurplus poncho tied over it by the corners. Estimated construction time: One minute. |  |

|

Marilyn and Jamie engaged in stability tests. Note the model of a "tensegrity" skinboat in foreground. |

Folding Umiak-Proa Project |

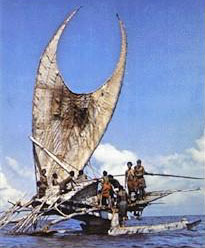

A Proa is a single-outrigger sailing canoe that is sailed with

the outrigger always to windward. This is Tevake's Tepuke trading canoe,

Taumako Island in the Solomons,

photographed in the '60s. This is one of the most beautiful things I've ever seen. |

|

| An Umiak is an undecked skinboat used in arctic cultures. This is Skip Snaith's "Sumiak", a bent-rib umiak-dory hybrid. I cried the first few times I looked at this picture. Buy his book. |  |

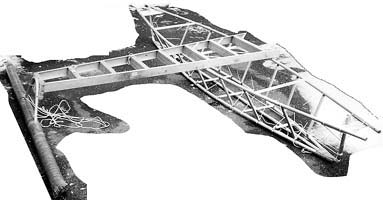

The outrigger is part of a stepladder. The outrigger is pipe insulation foam. The frame is made of aluminum tentpoles. The skin is closed-cell foam sandwitched between two layers of nylon cloth painted with rubberized roof paint. |

|

my folding umiak frame, frontview. Sort of based on these books: |

|

| Bow detail of frame. |  |

Chris, my biggest friend, testing the outrigger on the charles. It needs more buoyancy to be able to stand on the outrigger. |

|

|

|

River paddling on the river. Skin not yet painted, no foam between skin and frame. Surprisingly, it leaks very little. |

The Maiden Voyage |

| |

Before.

|

Hobenstein Proa |

|

The main hull is from a Hobie 16 catamaran. It sails just as well backwards. If you build one, ignore this picture and tilt the hull away from the outrigger 7.5 degrees as measured at the center of the deck. That makes it track right. The trampoline is a problem in high winds. Use a lattice of sticks instead. The sail is a couple of windsurfer sails sewed back-to-back. |

Local Proa Builders |

Ted

Warren |

|

|

|

John Ashworth |

(coming soon:)

(coming soon:)

(coming soon:)

butcher decwriters for robot parts.

make a stylish armchair from a shopping cart.

build a robot that opens padlocks from old floppy drives.

eat a dozen eggwhites and swim in cold water.

live in a car on Vassar St.

pick a mutual fund.

(coming soon:)

let the computers rehearse. let's make some music.

a 3-D zootrope sculpture.

the Jerkotron virtual reality ride.

Van Gogo the robot painter.

Van Gogo's masterpieces.

a very tall bicycle.

wood carvings done by a robot.

3D printed sculptures.

3D collage sculpture made by 3Dprinting 3Dscanned objects.

a simple 3Dscanner.

I hang out a lot at the MIT Electronics Research Society(MITERS) - a volcano-blossom of cultural and technical richness.

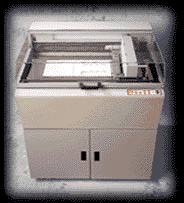

| at Zcorp we produce modelmaking

machines. The Z402 will build an object any shape at approx. 1.5 vertical

inches per hour, up to 8"x8"x10". It works by gluing particles

together with tiny droplets of binder. Minimum feature size is approx. .007"

YOU NEED ONE NOW. |

|

email me I'm robot( don't send me spam, replace this stuff between the parentheses with an 'at' sign )mit.edu aka Tim Anderson

the old homepage served me well for many years.

© 1997 ..99 Tim Anderson. All Rights Reserved.