|

|||||||||||||||||||||||||

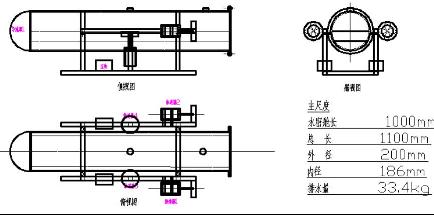

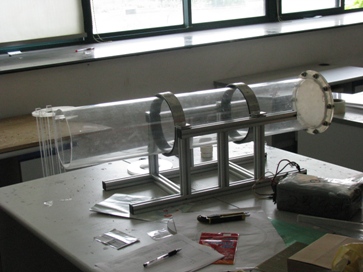

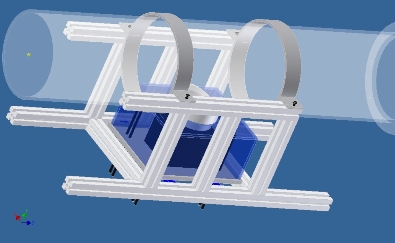

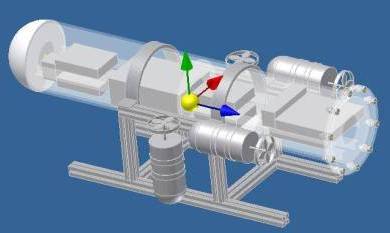

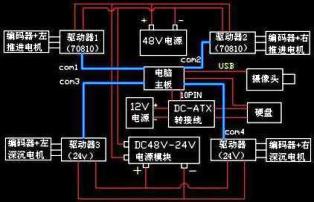

The "Flying Fish I" was the name of the first AUV(autonomous underwater vehicle) that our group designed and was bulit entirely by undergraduates. It was composed of one upper hull pressure vessel and the corresponding upper hull rack, with two vertical thrusters to control pitch and heave motions and two horizontal motors to drive the vehicle in the surge andyaw degrees of freedom. We built this AUV to in order to finish several underwater tasks, and our primary goal is to at last enter the AUVSI/ONR Underwater Vehicle Competition. My First Lab Experience:This AUV designing and building is actually the very first lab experience after I entered university. And I really learned a lot from this precious experience. during this interesting journey, I found my passion and interests into the research, and also explored the way how students performed it. Here special thanks to three seniors, Qian Peng, Meng Jinlong, Ma Shaojun, who gave me numerous help and instructions. Building Process:

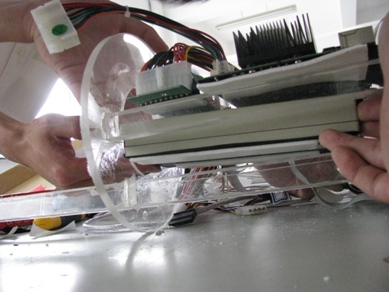

Then inside it was the core of the "Flying Fish I", the central controlling computer with the OS as Windows 98 and 4 Maxon motor control panels.

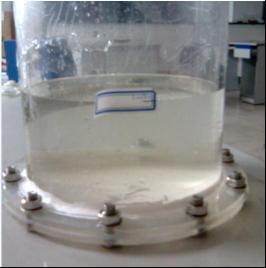

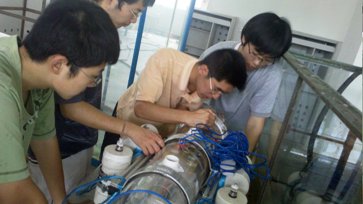

One of the biggest difficulties we met with is the watertight problem, including the underwater motors and the Connecting plugs.

Knowledge Related:

More Pictures:

|